Loading...

Loading...

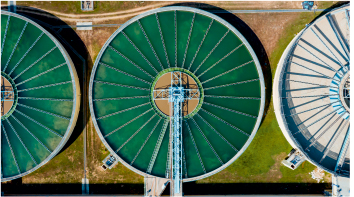

When solid/liquid separation, which is encountered in many industries with chemical treatment plants, is carried out efficiently, the burden of biological treatment plants is reduced. Thus, the aeration energy of biological treatment facilities is saved while the efficiency and lifespan of bacteria is extended.

With chemical treatment, inorganic impurities that can harm bacteria are removed from the system. The most important parameter in chemical treatment plants is that the chemicals used do not bring extra load, sludge or cost to the system. For this reason, organic, easy-to-use, low dosage products are preferred.

Surface active agents (lubricants, mold release agents, surfactants, etc.), which are frequently used in all industries, easily cause foaming in wastewater and reduce the efficiency of the treatment plant causing contamination of the facility and its environment as a result of excessive foaming. If the foam problem that is not conditioned properly is transferred to biological treatment and it causes bacteria to die due to lack of air and reduces the efficiency of biological treatment.

Water-based, silicone in emulsion form, oil-based and/or oil-ester emulsion defoamers in different concentrations.

Coagulation (aggregation) process is very important in wastewater treatment. Organic coagulants applied to wastewater in chemical treatment plants reduce and neutralize the electrical repulsion between suspended solid impurities. Thus, pollution causes particles to come together to form large lumps/clots. Depending on the physical and chemical properties of water, coagulants easily remove many pollutants from the system. Organic coagulants have lower dosages, are biodegradable, and do not disrupt the pH balance of the system, making them more advantageous than inorganic coagulants. Dye and color impurities, which are problems in many sectors, especially in textile, paper, packaging, viol, etc., are also removed from the system with the help of organic coagulants.

Polyamine with linear and branched organic polymer structure with different molecular weights and different viscosities; PoliDADMAC (PolyDadmac), Color Remover (PolyDCD) and various mixtures of these products.

Polymers are chemicals used in flocculation. Flocculation is the process of aggregating unstable particles into larger flocs. In the dewatering of unstable lumps formed by coagulants or settled sludge, it helps the suspended lumps / clots to come together more tightly and release water. Types of flocculants, that is, industrial polyacrylamides, are cationic, anionic or nonionic polyacrylamides. As Caran Water Technologies, we supply polyacrylamides with wide range of charge and molecular weight to end users in dry powder form or emulsion.

For the first time commercially in Turkey; Caran Water Technologies produces linear and/or branched flocculants with very high molecular weight in emulsion form. As Caran Water Technologies, we design our products according to the specific water characteristics of different industries such as wastewater plants, paper, food, steel, mineral and similar end users with high water usage

Anionic, Cationic and Nonionic Powder Polyacrylamides with wide molecular weight and different charges

Emulsion (Inverse Emulsion) Anionic and Cationic Polyacrylamides in different charges with high molecular weight as local production